Eliminating Solvent Bumping & Foaming during Evaporation

Complete the form below to unlock access to ALL audio articles.

The unique Dri-Pure® technology works by reducing pressure in the evaporation chamber in combination with an increase in rotor speed to achieve greater g-force and carefully controlling heat flow to the sample during the pressure ramping stage.

Embedded in the Genevac evaporator software and hardware, Dri-Pure works automatically without need for user intervention eliminating solvent bumping or foaming and enabling controlled ‘sample-safe’ solvent removal in the minimum time.

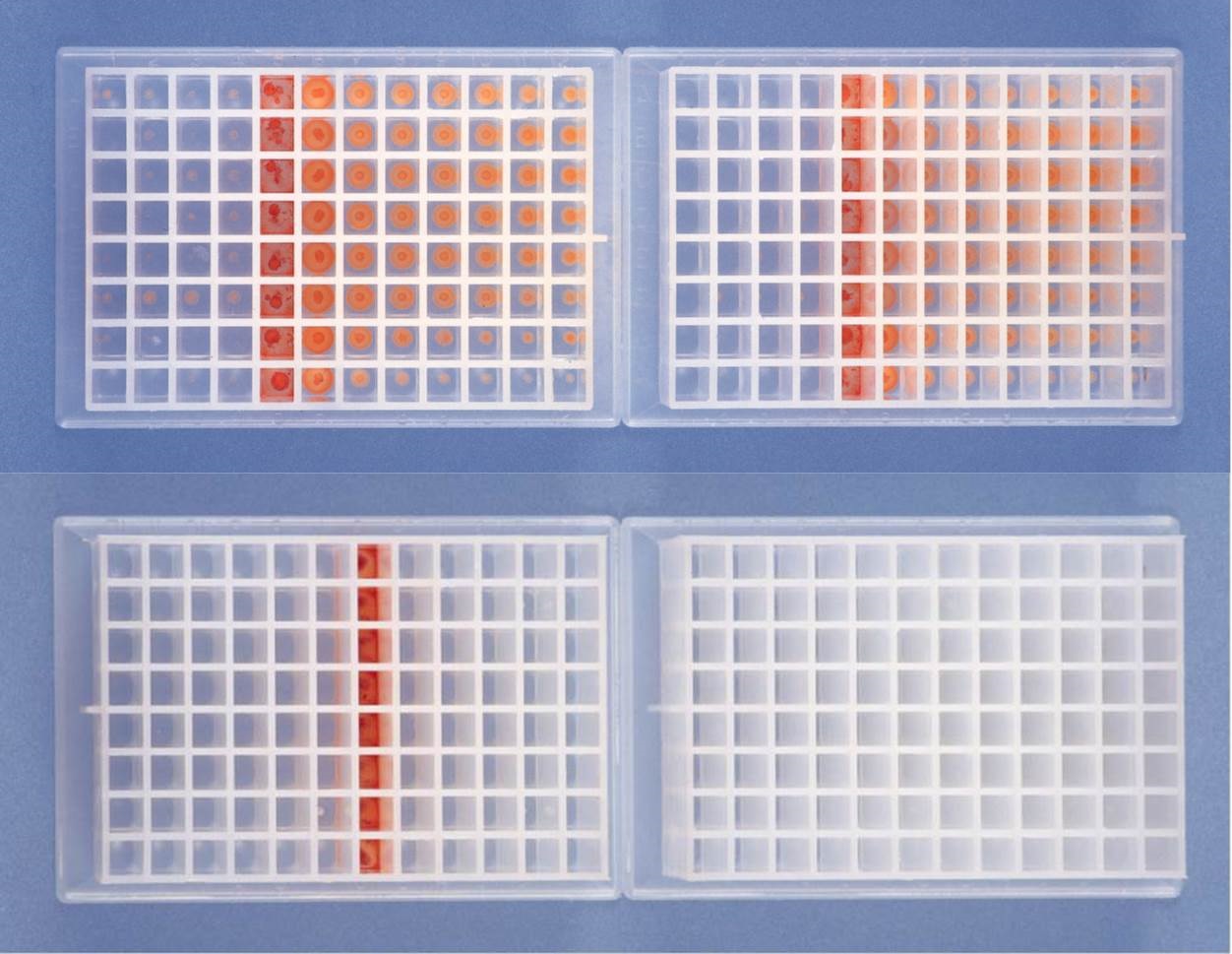

Dri-Pure® offers significant benefits and is widely proven to eliminate cross contamination during parallel evaporation in EZ-2 and HT evaporators. Dri-Pure® on the Rocket Synergy evaporator has been more recently demonstrated to prevent foaming often seen in batch evaporation of large volumes such as are generated by natural product extractions.

Combining Dri-Pure® with the auto-stop when dry capability - Genevac evaporators offer truly unattended evaporation freeing scientists to perform other tasks confident that their samples will be dried without cross contamination or thermal damage.