New Software Release for Freeze Drying Cycle Modelling

Complete the form below to unlock access to ALL audio articles.

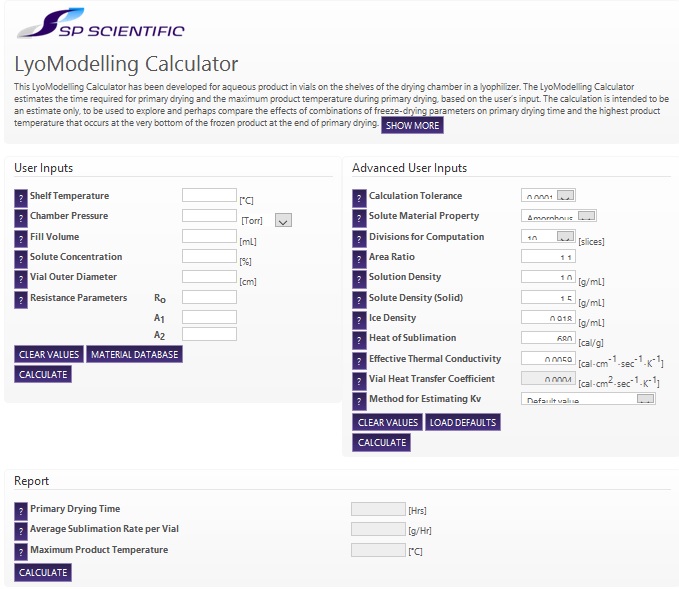

SP Scientific announces the introduction of the LyoModelling Calculator (LMC) - a powerful new software utility that enables those developing freeze drying cycles to calculate the time required for primary drying and the maximum product temperature based on user data input.

This free software resource is available on the SP Scientific website. Users obtain a starting point for primary drying duration and the maximum product temperature at the sublimation interface using pertinent information, such as shelf temperature and chamber pressure, from which an optimized freeze-drying cycle can be developed. The LMC is based on the steady-state heat and mass transfer model of primary drying developed by Dr. Michael Pikal with modifications by Dr. Robin Bogner and Royce Labriola at the University of Connecticut (USA).

The LyoModelling Calculator was developed for aqueous product in vials in direct contact with the shelves in a lyophilizer. Primary drying phase is a very important phase and typically the longest phase during the lyophilization process. Careful design of the primary drying phase is critical to ensure critical product temperature is not compromised during the sublimation process which could impact the final product quality attributes. The calculation is intended to be an estimate only, to be used to explore and compare the effects of combinations of freeze-drying parameters on primary drying time and understanding the product temperature dynamics during the primary drying process.