Green Button Go™: Increasing Traceability, Visibility and Compliance in the Lab

Complete the form below to unlock access to ALL audio articles.

Biosero, Inc. will release new Green Button Go™ software products and features, as well as a version that is certified 21 CFR Part 11 compliant, at the 2020 Society for Laboratory Automation and Screening Conference (SLAS 2020) in San Diego, California.

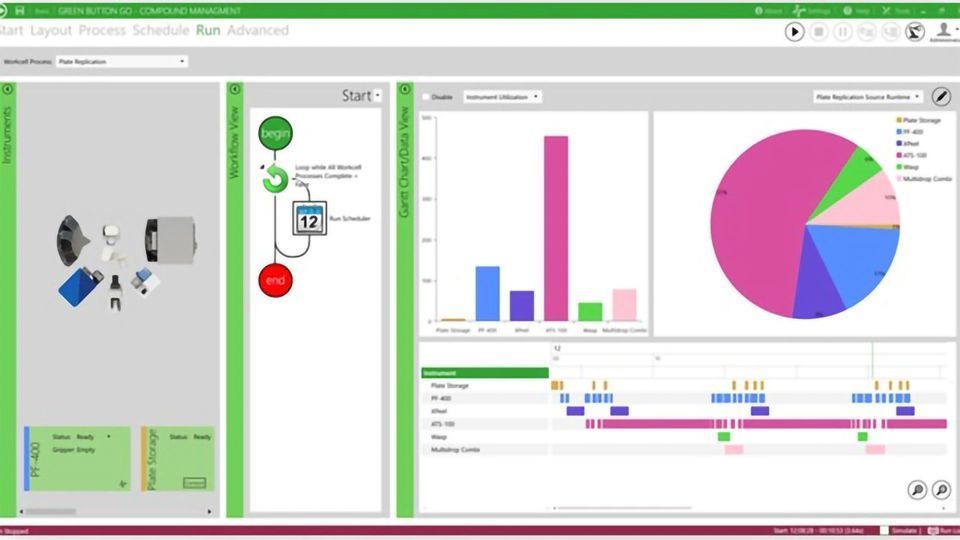

The new GBG Dashboard™ is designed to be an easy-to-use interface that provides comprehensive process visualization and oversight of outputs from several devices simultaneously. Working in sync with the Green Button Go Automation Scheduling Software, it gives a complete view of the operational outputs from several workcells or devices in the lab. GBG Dashboard includes the following features:

- The software provides a visual display of real-time instrument utilization across several modules to flag bottlenecks or unused capacity.

- It monitors the progress of runs across multiple workcells, including the percentage of the run completed on each workcell. GBG Dashboard also compares completed run statistics with failed or canceled runs.

- Reports the status and location of each plate in the run.

- Flags workcell and instrument level errors as well as uptime per unit.

- Generates comprehensive data comparisons for completed runs versus failed or canceled runs.

“Instead of moving from workcell to workcell to check each PC for run status and data, lab managers can use GBG Dashboard to monitor what is going on inside the lab, from any screen in the lab,” added Tom Gilman, CEO, Biosero. “With this valuable information, laboratory technicians, managers or management, can monitor workcell performance over time and make process improvements based on the information output.”

Assay Planning, Visualization and InApp Help Hallmarks of Green Button Go 2020 Software Release

The 2020 edition of Green Button Go Automation Scheduling Software remains a device-agnostic platform that fully automates any piece of lab equipment into a cohesive automation ecosystem. Offering more walk-away time, help tips and visualization tools, Green Button Go 2020 now has additional functionality:

- Assay Planning – Ensure that each assay plate receives uniform processing time with the new assay planning function in Green Button Go software. Input the number of plates into the software, and it calculates the most efficient method to run the plates. Increase throughput by adding new plates to the process at any time.

- Gantt Chart Visualization – Generate run data for all plates with timing output as a visual representation in a Gantt chart that shows how long each plate takes within a process.

- InApp Contextual Help – Users can hover over an icon to open contextual tips and pointers from the help documentation to access necessary guidance rapidly and with minimum effort.

Certified 21 CFR Part 11 Compliance

Green Button Go is now available in a version that is certified 21 CFR Part 11 Compliant, offering security and traceability for highly regulated laboratories. The Arbour Group, an independent global regulatory solutions organization serving the Life Sciences industry, validated the certification.

Green Button Go software with 21 CRF Part 11 certification has built-in tools to lock access to audit trails, record electronic signatures and support documentation required for electronic quality records.